Chemical Optimization

Stimulate specializes in the development and application of custom blends to remove liquids, sand, scale, and wax from downhole systems.

- Years experience

- 18+

- Specialized blends

- 20+

Boost Production

Cost-Effective Optimization

We provide advanced chemical optimization solutions to enhance well performance, restore production, and extend asset life for Montney & Duverney producers. Our specialized chemical treatments are formulated to address common downhole challenges—scale, sand, paraffin, H2S, and liquid loading.

Chemical Stimulation & Support

Chemical stimulation is a proven method to treat H2S, remove flow restrictions, and improve reservoir connectivity. Our targeted treatments are applied via batch or continuous injection.

D-Vour

- H₂S Elimination Solutions

- Liquid Scavengers: Fast-acting oxidizers, triazine, and non-triazine blends.

- Solid Scavengers: Iron oxide/hydroxide granular media and engineered systems for long-term H₂S control.

D-Liquefy

- Liquid & Solid Foamer Systems

- Liquid foamers optimized for Montney condensate-rich environments (up to 90% condensate tolerance).

- Solid stick foamers for sustained unloading in gassy, liquid-loaded wells.

D-Sand

- Sand Management Chemistry

- Sand Solvent (synthetic HF): Dissolves silica-based sand deposits.

- Sand Dispersant: Loosens compacted sand for easy removal from wellbore and flowlines.

D-Bung 1, 2, 3

- Large-Volume Batch Stimulation

Comprehensive cleanout solutions for wells plugged with salt, calcium/iron scales, sand, and liquids.

Pushed into the horizontal section, soaked, then aggressively flowed back to P-Tank / Flare.

Supported by gas lift compressors for optimal fluid displacement and recovery.- D-Bung 1: Sand/salt cleanout with foamer and suspension additives.

- D-Bung 2 / 2S: Multi-scale (carbonate/iron) + sand dispersion using HCl-based systems.

- D-Bung 3: Full-spectrum dissolution (silica, salt, iron, carbonate) using synthetic HF/HCl blends.

D-Par

- Wax Control Chemistry

- High-efficiency wax solvents and dispersants.

- Cost-effective prevention and remediation of paraffin buildup in tubing and flowlines.

D-Carb

- Organic, inorganic, and synthetic acids

Effectively dissolve carbonate scales in the wellbore, perforations, and pipelines.

Commonly “squeezed” into fractures to restore inflow and enhance near-wellbore permeability.

D-Tension

- Nano Surfactant – Nanoparticle micellar dispersion

Reduces interfacial tension to accelerate flowback and improve recovery rates in new and mature wells.

Proven in frac hit mitigation and rapid well recovery post-interference.

Chemical Injection & Supply

We deliver full-service chemical injection and supply for completion and production phases:

- Friction Reducers – Lower pumping pressures during fracturing.

- Biocides – Prevent microbial-induced corrosion and souring.

- Corrosion & Scale Inhibitors – Protect surface and downhole equipment.

- Oxidizers – Applied via specialized hardware for real-time H₂S removal.

Our field teams provide manpower, equipment, and custom chemical programs to ensure precise application and optimal results.

Field-Proven Application Process

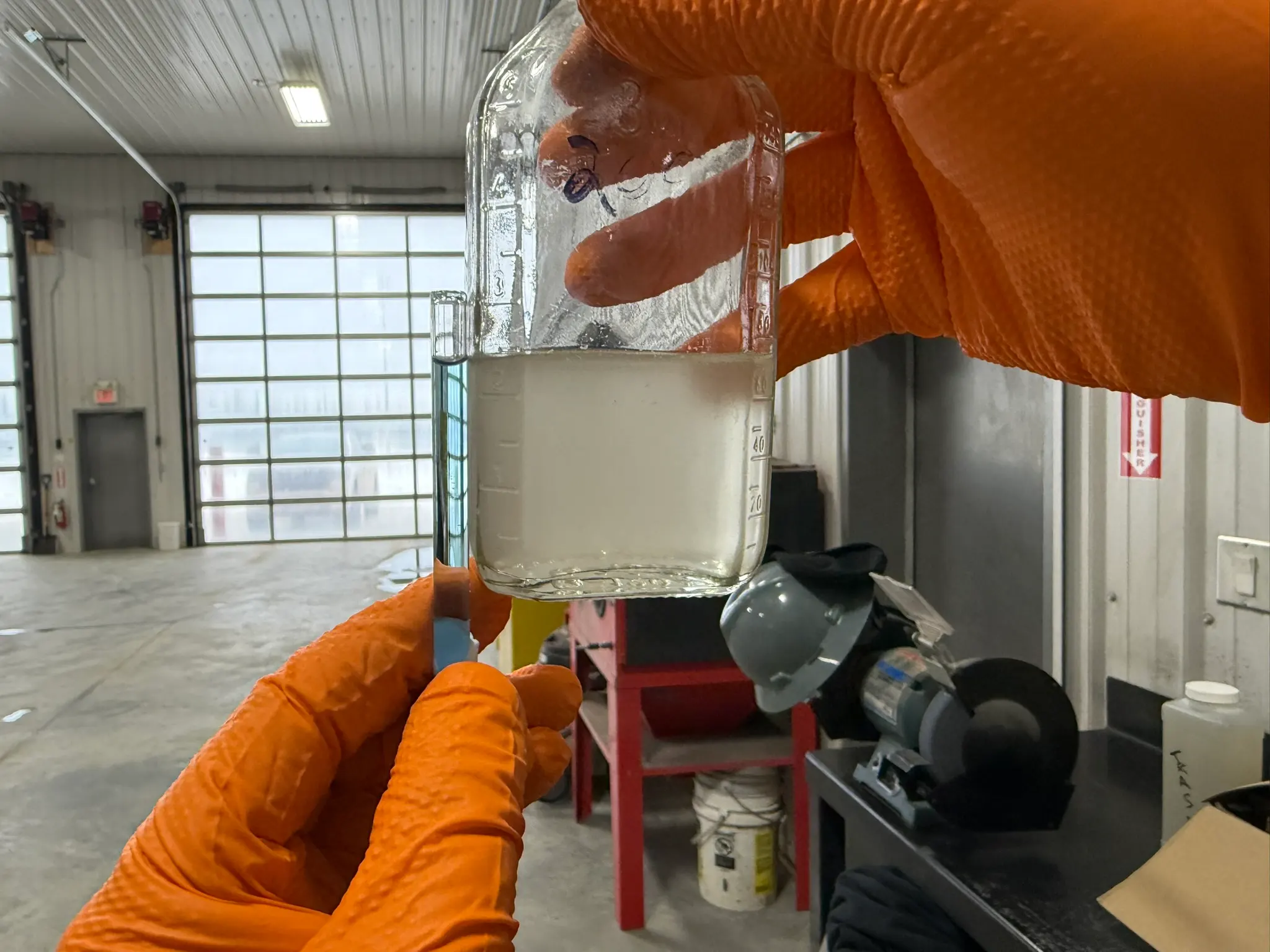

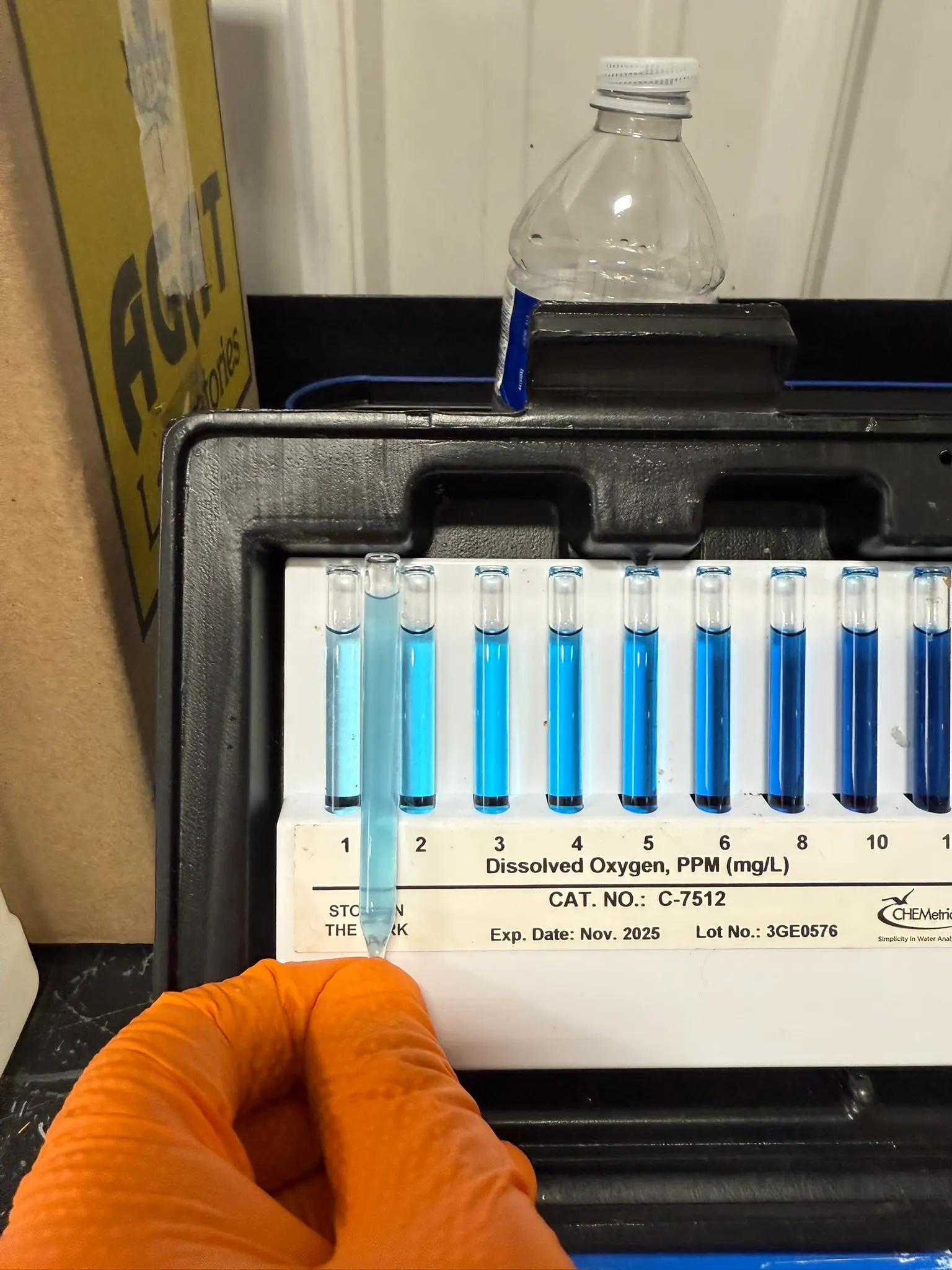

- Diagnosis – On-site fluid and deposit analysis.

- Custom Formulation – Tailored chemistry selection.

- Deployment – Batch, squeeze, or continuous injection.

- Monitoring – Regular sampling and performance tracking.

- Optimization – Adjust treatment volume and frequency for maximum ROI.

Boost Your Production

Ready to get more out of your operating area—and spend less doing it? Let’s talk.